Máy nén khí Chicago Pneumatic - Thương hiệu nổi tiếng đến từ Mỹ

Trải qua hơn một thế kỷ để sáng lập và phát triển bắt đầu từ năm 1901, Chicago Pneumatic (CP) đã trở thành nhà sản xuất máy nén khí hàng đầu không chỉ ở tại Mỹ mà còn ở cả thế giới. Vào đầu những năm 2000, Chicago Pneumatic từng bước tiến vào thị trường Việt Nam. CP từng bước khẳng định được bản thân có thể đáp ứng được mọi nhu cầu về khí nén và trở thành nhà cung cấp máy nén khí cho các công ty lớn, có tên tuổi. Với hệ thống phân phối, kỹ thuật và đội ngũ nhân viên dày dặn kinh nghiệm do được đào tạo bài bản, các sản phẩm máy nén khí Chicago Pneumatic được đảm bảo chắc chắn về điều kiện vận hành, bảo trì, bảo dưỡng tốt nhất, phụ tùng và vật tư tiêu hao được đáp ứng một cách nhanh chóng.

Máy nén khí Chicago Pneumatic được thiết kế và sản xuất với các dòng máy công nghiệp tiêu chuẩn, hiện đại phiên bản tích hợp bình nén khí và máy sấy khí.

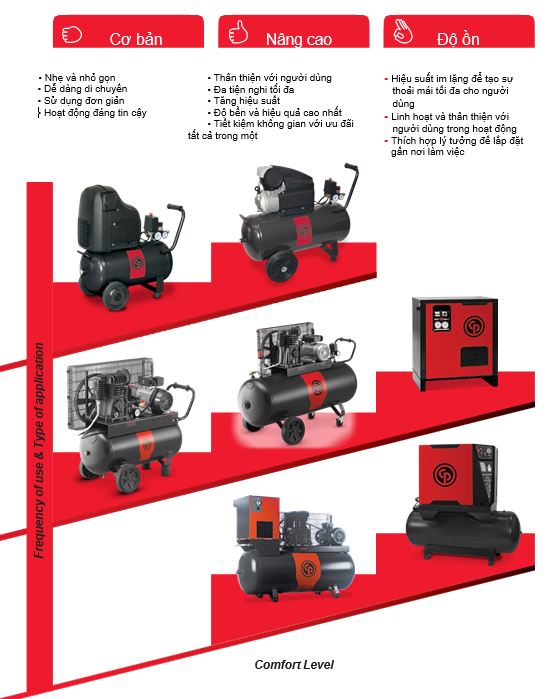

Phân loại máy nén khí Chicago Pneumatic

Cũng giống như các dòng máy nén khí khác, máy nén khí chicago cũng có 2 cơ chế hoạt động bằng piston và trục vít. Nhưng mỗi loại lại có nguyên lý hoạt động và cấu tạo khác nhau. Trong phần tiếp theo, chúng ta hãy cùng đi tìm hiểu máy nén khí piston Chicago Pneumatic và máy nén khí trục vít Chicago Pneumatic có ưu điểm, ứng dụng gì trong cuộc sống.

1. Máy nén khí piston Chicago Pneumatic

Máy nén khí piston Chicago Pneumatic là dòng máy dùng piston để nén khí. Máy nén khí piston là một máy nén dịch chuyển tích cực sử dụng một piston và xi lanh dẫn động trục khuỷu để nén không khí. Máy nén hai cấp bao gồm một bước bổ sung mà không khí được nén trong một giây.

Máy nén khí piston Chicago Pneumatic

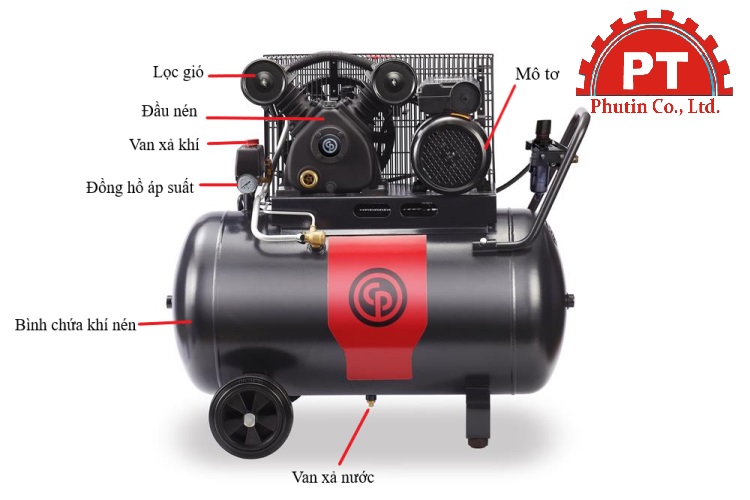

Cấu tạo máy nén khí piston Chicago Pneumatic

Về dòng máy nén khí piston Chicago Pneumatic có cấu tạo đơn giản hơn so với dòng máy nén khí trục vít. Bao gồm các chi tiết cơ bản sau:

- Mô tơ: là bộ phận quan trọng đối với khả năng chuyển đổi điện năng thành cơ năng nhằm cung cấp cho các bộ phận khác vận hành.

- Đầu nén: là nơi mà diễn ra quá trình nén không khí. Trong đầu nén lại gồm có nhiều chi tiết nhỏ như xilanh, piston, bạc đạn, tay dên, trục khuỷu,...

- Van an toàn: giúp đảm bảo an toàn cho hệ thống máy nén không bị gia tăng áp suất đột ngột gây mất an toàn.

- Van xả nước: có nhiệm vụ loại bỏ lượng nước đọng, hơi nước lẫn trong khí nén nhằm đảm bảo chất lượng nguồn khí cũng như tránh han gỉ cho các chi tiết máy cũng như các thiết bị sử dụng khí nén. Giúp cho khí nén sạch hoàn toàn 100%.

- Đồng hồ đo áp suất: hiển thị áp suất khí nén trong bình chứa khí giúp người dùng dễ theo dõi áp suất trong quá trình máy vận hành.

- Dây đai, puly: thực hiện quá trình truyền động cơ năng từ mô tơ đến đầu nén. Khi mô tơ quay làm puly quay, lúc này dây đai trên puly sẽ truyền cơ năng làm puly beeb đầu nén cùng quay.

- Lọc giúp: giúp hạn chế bụi, cặn bẩn theo luồng không khí đầu vào đi vào trong máy.

- Bình dầu: được gắn liền với hệ thống piston, cung cấp dầu bôi trơn liên tục cho hệ thống piston hoạt động. Giúp kiểm soát lượng dầu trong bình thông qua mắt thăm dầu.

- Bình chứa khí nén: hay bình tích áp dùng để tích trữ lưu lượng khí nén mà máy tạo ra. Khi bình được nạp đầy khí nén ở bên trong thì máy sẽ dừng nạp. Và ngược lại, khi lưu lượng bên trong không đủ theo yêu cầu sử dụng, máy nén khí sẽ tự động nạp thêm vào.

Nó còn có tác dụng điều hòa áp suất ở đầu ra, cung cấp khí nén đến các dụng cụ, thiết bị khác.

Ngoài những bộ phận kể trên thì máy nén khí piston còn gồm một số chi tiết khác đi kèm như hộp điện, rơ le, bánh xe, tay kéo, kim chỉ áp,...

Cấu tạo máy nén khí piston Chicago Pneumatic

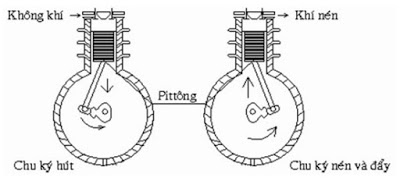

Nguyên lý làm việc của máy nén khí piston Chicago Pneumatic

Nguyên lý của máy nén khí piston Chicago Pneumatic hoạt động dựa trên sự tịnh tiến qua lại của piston nhờ được nối với cơ cấu thanh truyền, tay quay. Quá trình nén khí của máy nén khí piston diễn ra như sau:

- Máy sử dụng một xi-lanh có chứa piston ở trong. Khi piston máy nén khí di chuyển xuống, lượng không khí bên ngoài sẽ được hút vào đầu nén.

- Khi piston di chuyển lên sẽ thu hẹp thể tích khí làm cho áp lực khí tăng đến một mức nhất định. Mức áp lực này được xác định khi áp suất bên trong xi-lanh lớn hơn áp suất của dòng chảy.

- Lúc này van xả mở cho không khí thoát ra ngoài đi đến hệ thống khí nén. Đây là một quá trình nén khí cơ bản hay chính là nguyên lý làm việc của máy nén khí piston 1 cấp.

- Đối với máy nén khí piston 2 cấp, nguyên lý hoặc động sẽ khác đôi chút. Khí nén sau khi đã nén không trực tiếp đi vào hệ thống khí nén hay bình chứa mà lại được tiếp tục đưa lên bình làm mát để làm mát khí nén.

- Sau đó sẽ được đưa đến một xi-lanh khác để tiếp tục nén lần 2. Lúc này kết thúc quá trình nén thì khí mới được đưa vào bình chứa, kết thúc quá trình nén khí.

Nguyên lí làm việc máy nén khí piston Chicago Pneumatic

Chức năng máy nén khí piston Chicago Pneumatic

Máy nén khí piston Chicago Pneumatic có chức năng cung cấp lượng khí sạch với áp suất rất cao. Làm tăng áp suất của chất khí bằng cách piston chuyển động trong xilanh tạo áp lực đẩy khí nén vào bình trữ khí nén.

>> Xem thêm: Lắp đặt máy nén khi

Ứng dụng máy nén khí piston Chicago Pneumatic

Máy nén khí piston Chicago Pneumatic cung cấp khí nén với lượng khí nén lớn và rất ổn định. Được ứng dụng nhiều trong các lĩnh vực đời sống xã hội, hoạt động sản xuất, kinh doanh.

- Ứng dụng công nghiệp phun sơn: thường được dùng để phun sơn lên các cửa, tường rào, cổng trên nhiều bề mặt, kim loại, gỗ…

- Ứng dụng trong ngành thực phẩm, đồ uống, y tế: sản xuất thuốc, làm khô, bay hơi, đóng gói thực phẩm, đồ uống… không khí dành cho ngành thực phẩm, đồ uống, y tế đều phải có chất lượng cao. Với yêu cầu khắt khe, trong ngành chỉ sử dụng máy nén khí nhằm tách cặn bẩn, tạp chất, màu, mùi tạo nên chất lượng không khí cao.

- Ứng dụng trong sửa chữa, bảo dưỡng các loại xe, máy móc: máy nén khí piston cung cấp khí nén cho các loại máy móc, trang thiết bị như máy nén rửa xe, máy hút dầu, bình bọt tuyết, máy bơm mỡ, cầu nâng, bàn nâng, máy ra vào lốp, súng bắt ốc, bơm hơi xe,…

Ứng dụng máy nén khí piston vào lĩnh vực công nghiệp

Thông số kỹ thuật máy nén khí piston Chicago Pneumatic

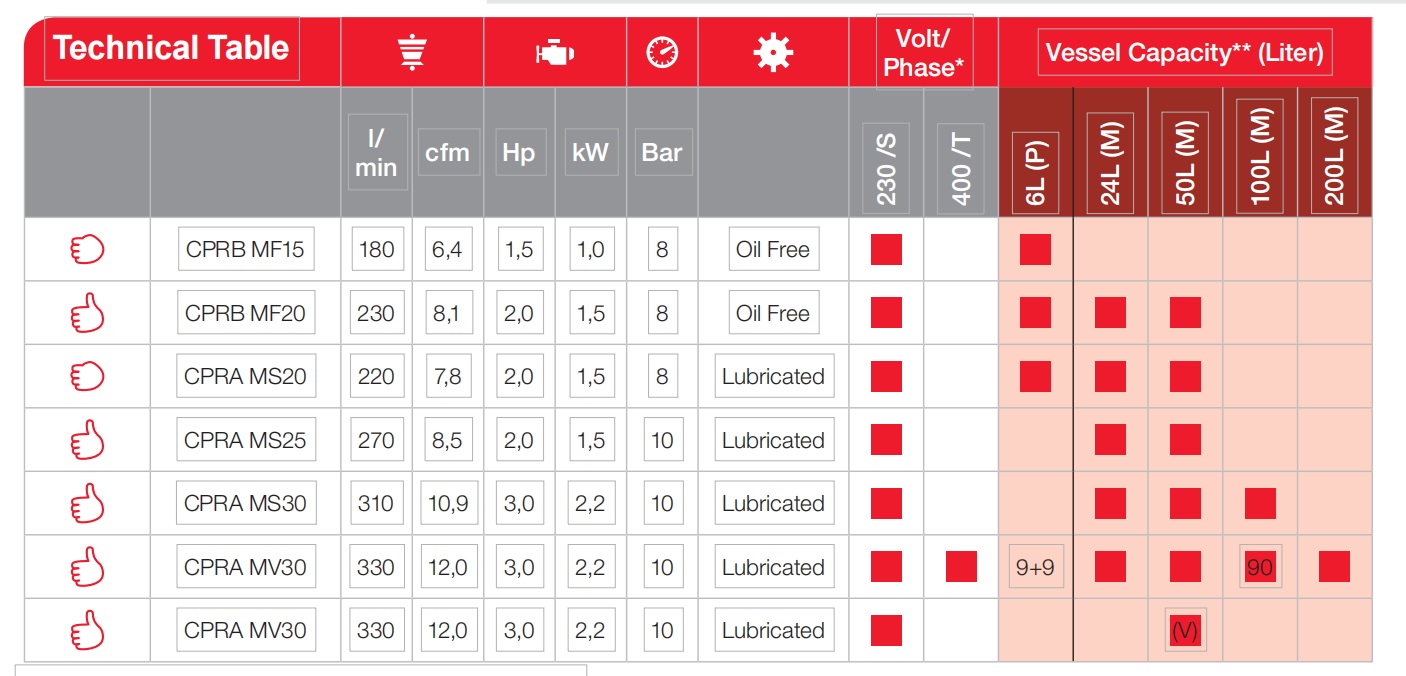

- Máy nén khí piston CPRA - CPRB

Lưu lượng: 180 - 340 lít/phút

Công suất: 1,5 - 3 HP

Áp suất làm việc: 8 - 10 bar

Bình chứa: 0 - 200 lít

Thông số kỹ thuật máy nén piston CPRA-CBPB

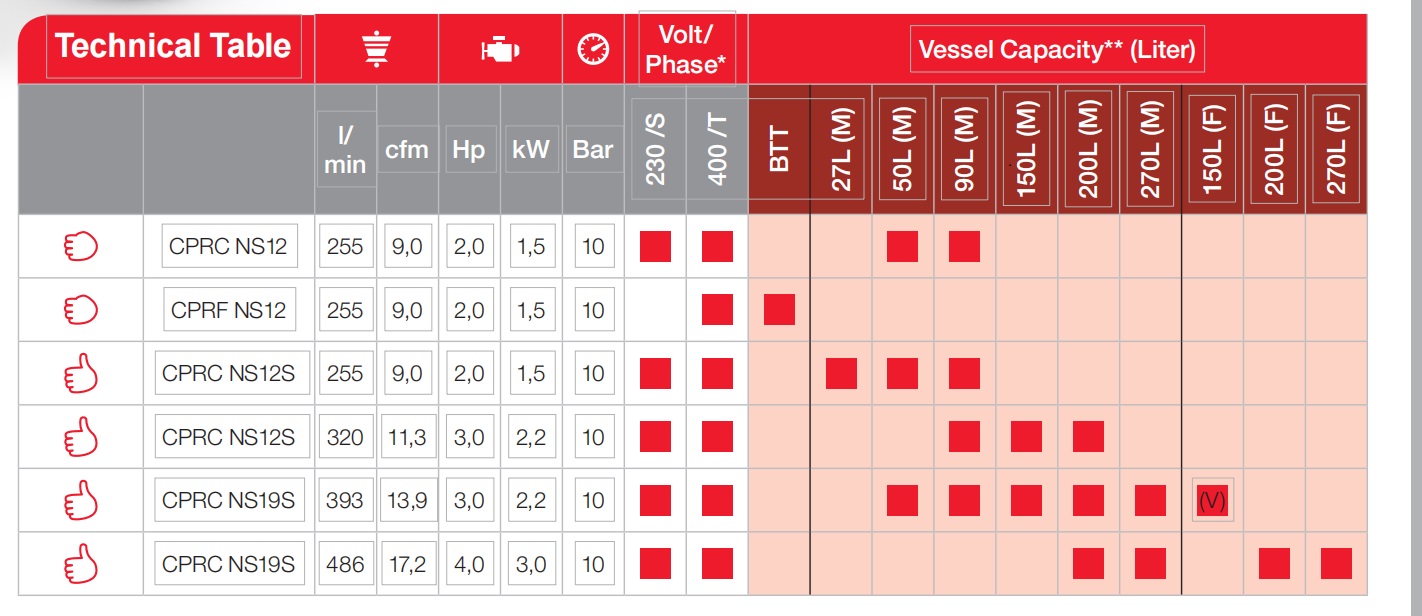

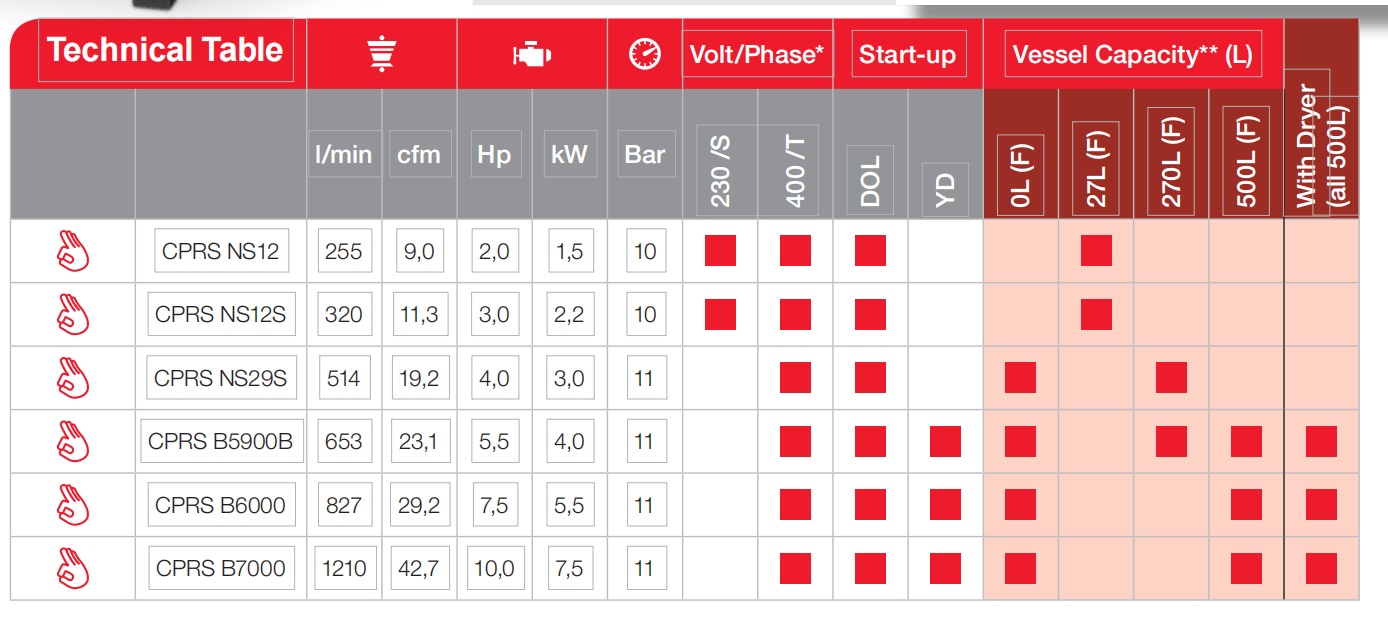

- Máy nén khí piston CPRC-CPRS

Lưu lượng: 201 - 486 lít/phút

Công suất: 2 - 4 HP

Áp suất làm việc: 10 bar

Bình chứa: 27 - 270 lít

Thông số kỹ thuật máy nén khí piston CPRC

Thông số kỹ thuật máy nén khí piston CPRS

- Máy nén khí piston CPRD - CPRO - CPRS

Lưu lượng: 514 - 2420 lít/phút

Áp suất làm việc: lên đến15 bar

Bình chứa: lên đến 900 lít

Thông số kỹ thuật máy nén khí piston CPRD

| | Motor Power | Working Pressure | Capacity |

| Ironman 2 - 100 | 2 HP | 10kg/cm2 | 300L/min |

| Ironman 3 - 140 | 3 HP | 10kg/cm2 | 400L/min |

| Ironman 5 - 270 | 5/5 HP | 10kg/cm2 | 720L/min |

| Ironman 7 - 270 | 7,5 HP | 10kg/cm2 | 1030L/min |

| Ironman 10 - 270 | 10 HP | 10kg/cm2 | 1740L/min |

Ưu và nhược điểm máy nén khí piston Chicago Pneumatic

- Tỷ số nén cao

- Có lớp sơn tĩnh điện cao cấp, tạo cho sản phẩm có vẻ ngoài bắt mắt đồng thời hạn chế sự oxi hóa của vỏ kim loại.

- Năng suất cao và áp suất rất cao giúp tốc độ nén khí nhanh và ổn định

- Giá thành rẻ

- Dễ sửa chữa, dễ dàng di chuyển

- Trong quá trình sử dụng không tiêu hao nhiều điện năng, giúp tiết kiệm nhiên liệu và điện.

- Có độ bền cao: máy nén khí piston có sử dụng hệ thống dầu bôi trơn giúp piston hoạt động liên tục với tần suất cao, hạn chế tối đa hỏng vặt. Chỉ cần cung cấp dầu bôi trơn thường xuyên, piston hoạt động liên tục tốt, độ bền cao.

Piston nhiều cấp làm mất trung gian tạo áp suất cao theo yêu cầu, có khả năng tạo áp suất cao khi sử dụng nhiều loại tầng.

- Hiệu suất thấp

- Ổn, rung động cao

- Áp suất và lưu lượng khí nén không đều vì chỉ khi ở kỳ nén mới có tác dụng nén khí

2. Máy nén khí trục vít Chicago Pneumatic

Theo tài liệu chuyên ngành “Máy nén khí trục vít là máy nén thể tích. Sử dụng cơ chế 2 trục vít xoắn ngược chiều nhau. Máy nén khí trục vít là máy nén khí duy nhất có thể đáp ứng được mọi nhu cầu công việc, công việc được vượt trội hơn hẳn về hiệu suất lẫn độ bền”.

Máy nén trục vít Chicago Pneumatic có thiết kế kiểu dáng đặc biệt và khác hoàn toàn so với máy piston. Có dạng hình hộp chữ nhật gọn gàng, đẹp mắt với các góc cạnh vuông vắn giống như một chiếc tủ. Thường được sử dụng để thay thế cho máy nén khí piston khi cần khối lượng khí nén lớn, áp suất khí cao trong các ứng dụng về ngành công nghiệp lớn.

Máy nén khí trục vít Chicago Pneumatic

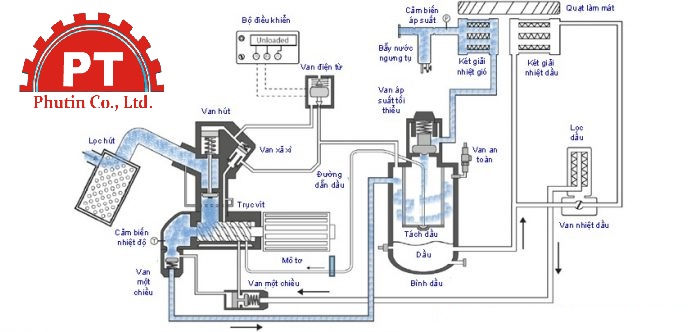

Cấu tạo máy nén khí trục vít Chicago Pneumatic

Máy nén khí trục vít Chicago Pneumatic có cấu tạo khá phức tạp. Máy nén khí trục vít CP có cấu tạo theo nguyên lý ăn khớp giữa các trục vít với nhau hoặc qua một cặp hoặc vài cặp bánh răng ăn khớp. Có thể làm việc với số vòng quay cao, và do vậy có thể giảm khối lượng và kích thước. Cũng do cấu tạo như vậy nên máy nén trục vít có dao động về lưu lượng rất thấp. Máy nén hoàn toàn cân bằng và không cần phải có đế đặc biệt.

Cấu tạo máy nén khí trục vít Chicago Pneumatic

Máy nén khí trục vít Chicago Pnuematic bao gồm các chi tiết sau:

- Cụm đầu nén: Là nơi phụ trách việc nén khí. Trong cụm đầu nén còn gồm các bộ phận khác như mô tơ, dây đai, bánh răng, trục vít,..

- Mô tơ điện và bộ coupling: Hầu hết các máy nén khí trục vít đều sử dụng mô tơ 3 pha. Bộ phận này có nhiệm vụ chuyển hóa điện năng thành cơ năng.

- Van hút: Có nhiệm vụ điều chỉnh lưu lượng của lượng khí nén đầu vào của máy.

- Van một chiều: Được lắp tại đầu ra của khí nén có nhiệm vụ cho khí chỉ đi theo một hướng xác định.

- Van chặn dầu: Nằm ở dưới đáy của cụm đầu nén có nhiệm vụ ngăn chặn dầu tràn từ đầu nén khí sang mô tơ khi máy không vận hành.

- Van áp suất tối thiểu: Loại van này giúp duy trì áp suất tối thiểu tại bình dầu. Chúng cũng có chức năng tương tự van một chiều.

- Van hằng nhiệt: Có nhiệm vụ điều tiết lượng dầu nhờn đi lên trên két làm mát.

- Van điện từ: Có nhiệm vụ đóng, mở cổ hút.

- Van an toàn: Đảm bảo máy luôn an toàn trước các sự cố chập, cháy.

- Bình chứa dầu và lọc tách dầu: Bình có nhiệm vụ chứa dầu máy. Lọc tách sẽ loại bỏ dầu máy ra khỏi khí nén, đảm bảo chất lượng khí.

- Đường ống hồi dầu: Có nhiệm vụ thu dầu dưới đáy có lọc tách dầu đọng lại sau quá trình lọc.

- Lọc dầu: Loại lọc này giúp lọc các cặn bẩn trong dầu, được lắp đặt giữa bình dầu và trục vít.

- Lọc sơ cấp: Giúp hạn chế sự tác động từ cát sỏi, bụi bẩn,... vào máy.

- Bộ giải nhiệt: Làm giảm nhiệt cho khí nén trước khi đưa ra khỏi bình chứa.

- Két giải nhiệt dầu: Bộ phận này đặt cạnh bộ làm mát với khả năng làm mát dầu và khí nén.

- Quạt làm mát: Cho khả năng thổi không khí ở xung quanh bộ làm mát dầu và khí nén.

- Cảm biến áp suất: Điều khiển máy bơm hơi hoạt động trong giải áp suất định mức.

- Cảm biến nhiệt độ: Có nhiệm vụ đo nhiệt độ của máy và đưa ra những cảnh báo nếu như nhiệt độ máy quá cao.

- Cảm biến quá tải: Hay chính là rơ le, giúp bảo vệ máy khỏi những sự cố chập, cháy, hoạt động sai.

Ngoài những bộ phận đã kể trên thì máy nén khí trục vít còn gồm nhiều bộ phận khác như công tắc, màn hình điều khiển LCD, vỏ bảo vệ,...

Các chi tiết trong máy nén khí trục vít Chicago Pneumatic

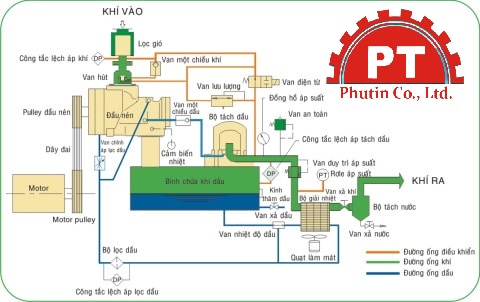

Nguyên lý hoạt động của máy nén khí trục vít Chicago Pnuematic

Cơ chế hoạt động: sử dụng cơ chế quay tích cực, xoắn từ dưới lên trên, từ ngoài vào trong để tạo ra áp suất lớn hơn. Hoạt động theo nguyên lý thay đổi thể tích liên tục, dựa trên hai trục làm trọng tâm. Bao gồm một trục lớn và một trục nhỏ (trục chính và trục phụ).

Trong đầu nén của hệ thống máy nén khí trục vít sẽ có 2 trục vít là 1 trục chính và 1 trục phụ. Hai trục này có các rãnh răng với khả năng ăn khớp nhau. Số răng giữa hai trục có sự khác biệt từ 1 – 2 răng. Khi vận hành, hai trục vít này sẽ quay ngược chiều nhau vì vậy mà khe hở giữa hai trục và vỏ bọc rất nhỏ.

Nguyên lý hoạt động máy nén khí trục vít Chicago Pneumatic

Khi máy nén khí khởi động, quan sát từ phía cửa hút chúng ta có thể thấy cặp bánh răng sẽ nhả khớp, các hốc giữa của bánh răng bị tách ra xa nhau để tạo ra một khoảng lớn. Khoang này thông với cửa hút nên được lấp đầy bởi không khí. Quá trình hút khí sẽ dừng lại khi khoang chứa khí đó giãn hoàn toàn, thể tích khí đạt giá trị lớn nhất.

Khi trục quay với tốc độ nhanh, không khí sẽ được hút vào trong vỏ thông qua cửa nạp đồng thời truyền thẳng vào khoang khí giữa hai trục. Khoang này sẽ được thu hẹp nhờ các bánh răng siết lại từ đó thể tích khí bị giảm đồng thời gia tăng áp suất cho khí. Để hạn chế sự rò rỉ của khí nén, van một chiều được lắp đặt ở cửa xả ngăn không cho khí nén đi ngược lại.

>> Xem thêm: Các lỗi thường gặp về máy né khí

Chức năng của máy nén khí trục vít Chicago Pneumatic

Máy nén khí trục vít Chicago Pneumatic có chức năng làm tăng áp suất của chất khí bằng cách nén để giảm thể tích thông qua cơ chế 2 trục vít xoắn ngược chiều nhau.

Ứng dụng của máy nén khí trục vít Chicago Pneumatic

Do các tính năng vượt trội của máy nén khí trục vít Chicago Pneumatic vì vậy được áp dụng rộng rãi trong mọi lĩnh vực đời sống như:

- Trong ngành điện tử công nghiệp: lượng khí nén từ máy nén không khí trục vít được dùng để hỗ trợ quá trình sản xuất các linh kiện điện tử, lắp ráp linh kiện điện tử. Trong ngành chế tạo khí nén thường được dùng để điều khiển các thiết bị tự động hóa. Ví dụ như máy cắt thanh nhôm sẽ được điều khiển bởi khí nén. Ngoài ra, khí nén từ thiết bị này còn được sử dụng để xì sạch bụi bẩn và đóng gói

- Trong ngành xây dựng: máy nén khí trục vít Chicago Pneumatic trong xây dựng sẽ cung cấp khí nén để vận chuyển, phun bê tông trong những điều kiện không thể sử dụng máy trộn bê tông. Ngoài ra khí nén còn dùng đế cấp cho các dụng cụ khoan để khoan lỗ, khoan tường, súng phun sơn,…

- Ngành công nghiệp khai khoáng: do đây là môi trường làm việc đặc thù là dưới lòng đất nên cần sử dụng máy nén khí trục vít không dầu để cung cấp khí nén sạch chứa khí oxy đưa xuống hầm, mỏ,…cho các công nhân.

- Ngành y tế: sấy khô, khử trùng các thiết bị y tế; sấy khô thuốc, tạo môi trường lý tưởng trong các phòng hóa sinh; cấp khí nén cho các thiết bị như máy X - Quang, tay khoan,...

Ứng dụng máy nén khí trục vít Chicago Pnuematic trong lĩnh vực công nghệ

Thông số kỹ thuật máy nén khí trục vít

Máy nén khí trục vít được chia thành nhiều dòng khác nhau. Hãy cùng Phú Tín đưa ra thông số kỹ thuật của từng dòng trong bài viết này.

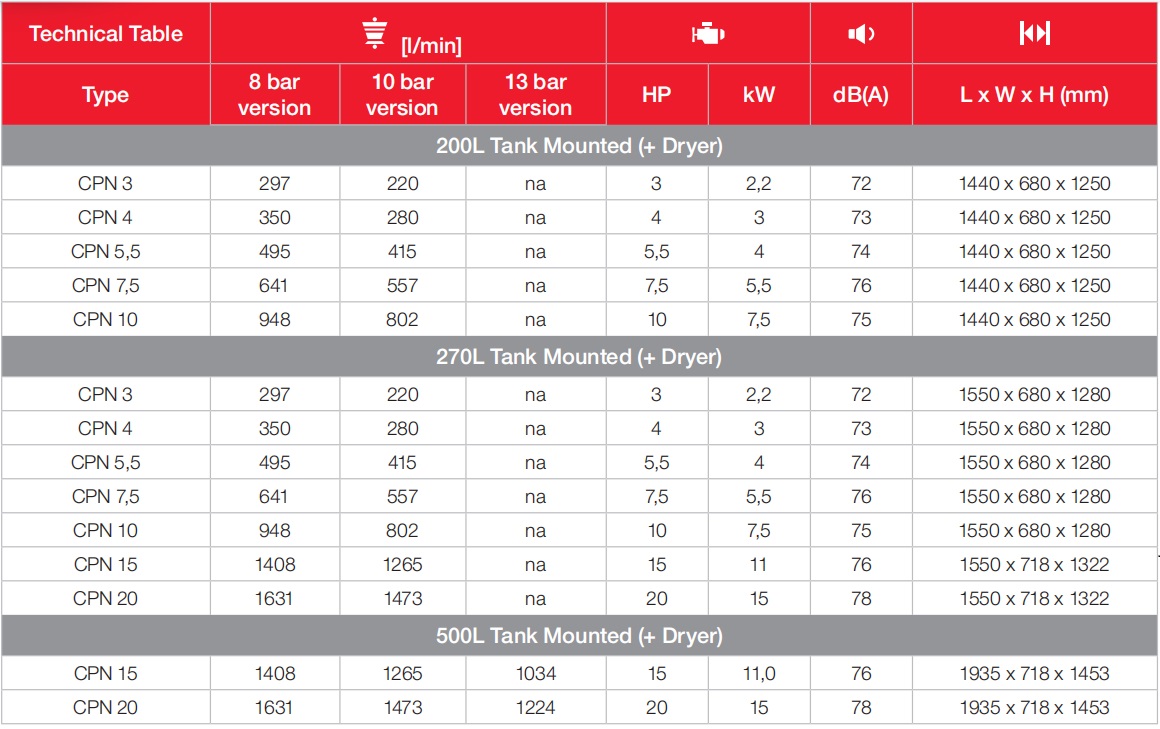

- Máy nén khí trục vít CPN

Bình chứa: 200, 270 hoặc 500 lít

Lưu lượng: 220 - 1631 lít/phút

Công suất: 3-20 hp / 2,2-15 kW

Áp suất làm việc: 8 - 13bar

Thông số kỹ thuật máy nén khí trục vít CPN

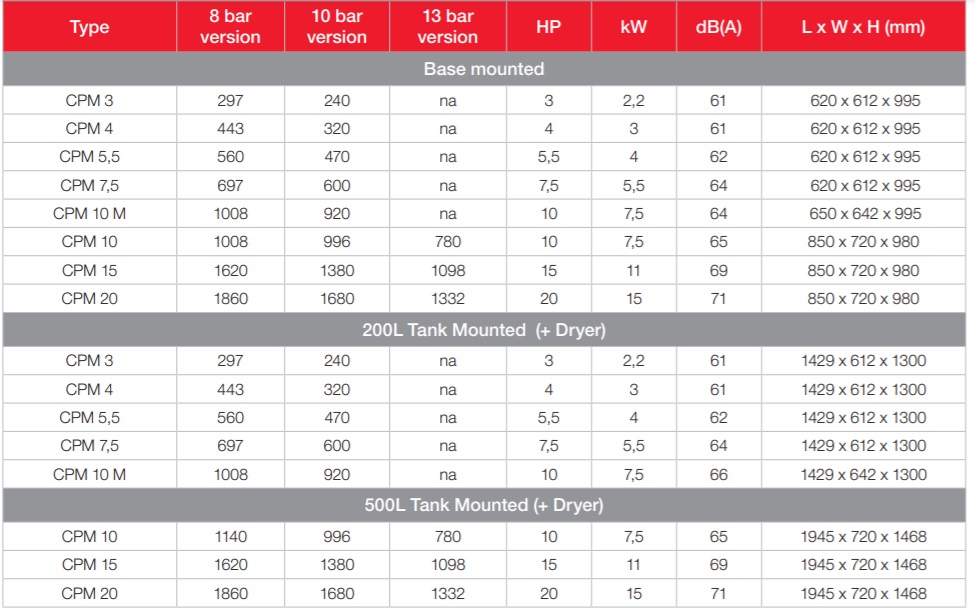

- Máy nén khí trục vít CPM

Bình chứa: 0, 200, 270, 500 lít

Lưu lượng: 240 - 1860 lít/phút

Công suất: 3-20 hp / 2,2-15 kW

Áp suất làm việc: 8 - 13bar

Thông số kỹ thuật máy nén khí trục vít CPM

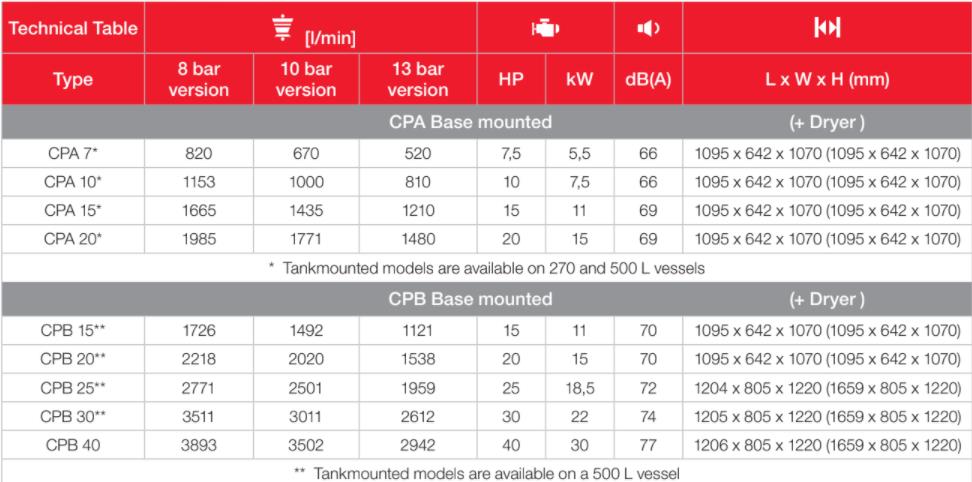

- Máy nén khí trục vít CPA-CPB-CPBg

Công suất: 7,5-50hp/5,5-37 kW

Áp suất làm việc: 7,5 - 13bar

Cân nặng: 251 - 905 kg

Lưu lượng: 520 - 6100 lít/phút

Bình chứa: 0, 200, 270, 500 lít

Độ ồn: 66-77 dB(A)

Thông số kỹ thuật máy nén khí trục vít CPA-CPB

Thông số kỹ thuật máy nén khí trục vít CPBg

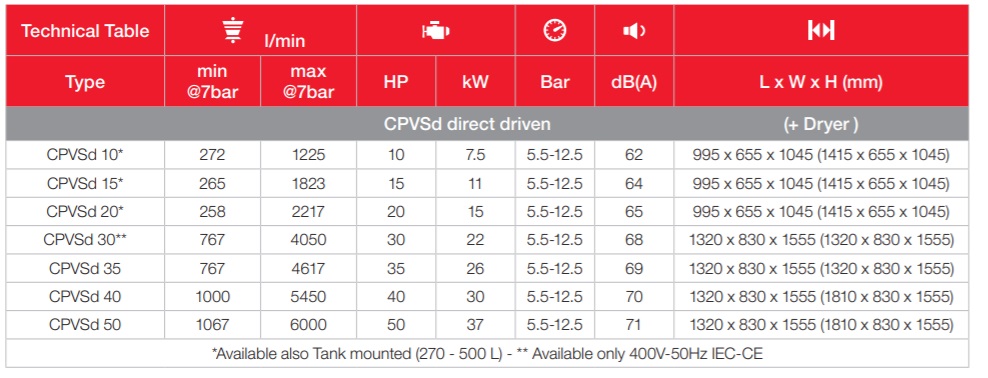

- Máy nén khí trục vít CPVS-CPVSd

Bình chứa: 0, 200, 270, 500 lít

Lưu lượng: 300 - 6000 lít/phút

Công suất: 10-50hp/7,5-37 kW

Áp suất làm việc: 5,5 - 12,5bar

Thông số kỹ thuật máy nén khí trục vít CPVS

Thông số kỹ thuật máy nén khí trục vít CPVSd

Ưu, nhược điểm máy nén khí trục vít Chicago Pneumatic

Ưu điểm:

- Không có van nạp, van đẩy

- Hiệu suất đẩy tải cao

- Hiệu suất lưu lượng tăng theo thời gian

- Lưu lượng đều, cao.

- Thiết kế nhỏ, gọn, độ bền cao (hai vít quay không tiếp xúc thân máy). Phần vỏ bên ngoài làm bằng kim loại có độ bền chắc chắn, có khả năng chống nước, chống bám bụi góp phần bảo vệ các chi tiết bên trong thiết bị.

- Vận hành êm, độ rung, độ ồn thấp. Do thiết kế lớp vỏ cách âm tốt so với các máy nén khí khác trên thị trường

- Ít tốn công bảo trì, chi phí vận hành thấp

Nhược điểm: - Giá thành cao hơn

- Yêu cầu bảo dưỡng thường xuyên theo định kỳ nhà sản xuất khuyến cáo và sử dụng phức tạp hơn

3. Địa chỉ phân phối máy nén khí Chicago Pneumatic chính hãng

Hiện nay trên thị trường máy nén khí không khó để tìm được một đơn vị cũng cấp sản phẩm máy nén khí Chicago giá rẻ, uy tín, chất lượng. Với 10 năm kinh nghiệm trong lĩnh vực

máy nén khí, là đại diện phân phối chính hãng máy nén khí từ Mỹ và Châu Âu, Đức, Đài Loan...Công ty Phú Tín đã được rất nhiều khách hàng đánh giá cao, đội ngũ kỹ thuật giỏi, được đào tạo đúng chuyên môn, lắp đặt và hướng dẫn vận hành theo đúng tiêu chuẩn nhà sản xuất.

Tại đây chúng tôi cung cấp các dòng máy nén khi đến từ nhiều thương hiệu như: Swan, Hertz, Kimair... đảm bảo chính hãng. Quý khách hàng có thể đến địa chỉ Đại lộ Bình Dương, Khu phố 3A, P. Thới Hòa, Tx. Bến Cát, Bình Dương để tham khảo sản phẩm máy nén khí chicago của chúng tôi.

Phú Tín hiện nay đang cung cấp dịch vụ bán máy nén khí Chicago online, chuyển hàng toàn quốc. Quý khách hàng có nhu cầu tham khảo, đặt mua máy nén khí Chicago vui lòng liên hệ đến chúng tôi theo số Hotline: 0274.3555.108 - 0933.384.579 hoặc Quý khách hàng mua máy nén khí Chicago online tại website:

phutin.com sẽ không chịu bất cứ rủi ro nào.

Cam kết của chúng tôi khi đưa sản phẩm đến tay khách hàng:

- Máy nén khí Chicago đúng giá, đúng chất lượng

- Nguồn gốc xuất xứ rõ ràng, chống hàng giả

- Giao hàng đúng thông số kỹ thuật

- Bảo hành đúng với thời gian bảo hành của nhà sản xuất

- Giao hàng miễn phí, thu tiền tại nhà

- Quý khách hàng được kiểm tra hàng trước khi thanh toán

Chúc Quý khách hàng lựa chọn cho mình sản phẩm ưng ý nhất!