1. On-site nitrogen generators

We offer a wide rage of nitrogen PSA generators and as well as a membrane solution

- Nordic solution - Designed for harsh environment: Quality-centric, eco-friendly, space-saving modular PSA solution

- Twin Tower solution - Best-in-class industry standard: PSA solution with a proven track-record throughout four decades

- Membrane solution - Perfect for retrofit: Flexible membrane solution with world's smallest footprint

- Compact solution - Low capacity: Nitrogen applications with low-capacity requirements

2. Feature

- Lowest energy consumption: PSA N2 generators from OXYMAT have the lowest energy consumption on the market. Our continuous R&D has resulted in power consumption down to 0.22 kW/Nm3 @ 95% purity

- Highest quality: Our production is highly standardised. All materials are prepared according to offshore specifications. Piping is made from SS316L and surfaces are powder coated in C4 grade paint.

- 24-hour support: Our service team is standing by to assist you remotely 24/7. We carry out service worldwide and work with our many service partners across the globe to keep your nitrogen generation plant operational.

WE PROVIDE STATE-OF-THE-ART DESIGN OXYMAT MODULAR PSA NITROGEN GENERATORS

By investing heavily in an ultra-modern production facility and rethinking our design, we have managed to eliminate a large portion of our variable costs. Our modular units are made in superior quality, and costs are kept down due to simplified production, lower storage costs and unified sourcing. This means competitive pricing for you when comparing OXYMAT to other nitrogen plant manufacturers.

OXYMAT X-SERIES FRAME-MOUNTED SOLUTIONS

If you are looking for a large capacity nitrogen generation package, and footprint is critical, our frame-mounted N2 generators are quite simply best value for money. The system is plug-and-play and the design is well-proven with well over one hundred installations around the globe.

3. Product

OXYMAT modular PSA N2 generators

N2 generator pressure vessels

Oxymat custom engineered projects

Each project is custom-built

- At OXYMAT, we listen to your demands and design the best possible solution for you. You can get the full line from air compressor to high quality cylinders – whatever your need may be.

Oxymat custom engineered psa systems

- We design your specific solution based on application, capacity, purity, pressure, classification requirements, ambient conditions and height above sea level. The more info you can provide us with, the better the solution we can deliver.

Oxymat's custom engineered projects include

- Our systems are placed in more than 130 countries in very different conditions and are used for various applications. Our customers include large gas companies, shipyards, refineries and gold mining companies. Each project has its own challenges and we are up to the task – every time.

Oxymat x-series frame-mounted solutions

4. Nitrogen applications

OXYMAT supplies nitrogen gas generators for all types of industries

Nitrogen gas generator applications

OXYMAT PSA nitrogen generators can be used in a wide range of applications within many different sectors such as:Modified atmosphere packaging, inerting, blanketing, purging, tire filling, food and beverage packaging, coal mines, marine, laser cutting, electronics, laboratories, oil & gas, and many more.

4.1 Food and beverages

Oxygen is a culprit in food spoilage and provides good basis for bacterial growth. Nitrogen is perfect for flushing and regulating the air out of the packaging. Want to know more on how we can help? Ask one of our experts.

- Food: Oxygen is a culprit in food spoilage and provides good basis for bacterial growth. Nitrogen is perfect for flushing and regulating the air out of the packaging.

- Beverage: In the beverage industry, nitrogen is used in packaging of carbonated or still beverages, beer, wine, juice drinks, tea, bottled water etc.

- Advantages: OXYMAT understands your need for a safe and reliable source of nitrogen. Our units offer small footprints and low noise levels, which makes it possible to install the units in most factories

Applications include

- Nitrogen inerting and blanketing

- Controlled atmosphere storage (CAS)

- Pest Control and grain fumigation

- Modified atmosphere packaging (MAP)

- Undercover gassing

- Nitrogen injection

- Sparging/stripping

- Purging

- Nitrogen flushing

- Aerosol propellant

- Beverage mixing/dispensing

Advantages of OXYMAT nitrogen generators

- Very low OPEX compared to cylinders or liquid gas

- Remove the hassle of handling cylinders

- No need to rely on external gas suppliers and fluctuating prices

- Improve quality and shelf life of air-sensitive materials

- Increase exports to long distance markets

- To maintain and preserve freshness of packaged or bulk foods

- Delaying rancidity and other forms of oxidative damage

- Serving as an inert replacement for air where oxidation is undesirable

- Slow down the decay process

- Prolong the shelf life of raw fresh and processed foods

- Eliminate bugs and micro-organisms

4.2 Pharmaceutical

Our on-site nitrogen PSA generators for the pharmaceutical industry are used in packaging of pharmaceuticals and serve as an inert gas where oxidation is undesirable. Want to know more on how we can help? Ask one of our experts.

- Controlled atmosphere storage (CAS): CAS is a technologically advanced storage method for which temperature, humidity and the levels of oxygen and carbon dioxide are precisely controlled.

- Modified atmosphere packaging (MAP): MAP is used to preserve the quality of pharmaceutical and medical device products, by controlling the composition of oxygen, carbon dioxide and nitrogen.

- OXYMAT advantages: OXYMAT recognizes the requirement for a reliable and safe source of N2. OXYMAT units offer small footprints and low noise levels and can be installed in most factories.

Applications include

- Nitrogen inerting and blanketing

- Controlled atmosphere storage (CAS)

- Pest control and grain fumigation

- Modified atmosphere packaging (MAP)

- Undercover gassing

- Nitrogen injection

- Sparging/stripping

- Purging

- Nitrogen flushing

- Aerosol propellant

- Beverage mixing/dispensing

Advantages of OXYMAT nitrogen generators

- Very low OPEX compared to liquid gas and cylinders

- Remove the hassle of handling cylinders

- No need to rely on external gas suppliers and fluctuating prices

- To maintain and preserve pharmaceuticals

- Serving as an inert replacement for air where oxidation is undesirable

- Slow down the decay process

- Extend the shelf life of pharmaceuticals

4.3 Marine

Our marine nitrogen generators have the smallest footprint and lowest energy consumption on the market. Nitrogen is used for several marine applications. Want to know more on how we can help? Ask one of our experts.

- Gas carriers: OXYMAT has delivered more than 60 units for gas carriers. Mainly for Korean yards and gas handling package suppliers. We offer high quality solutions with low OPEX and CAPEX. Flexible purities.

- Chemical tankers: OXYMAT has delivered more than 150 units for chemical tankers. Many units have been delivered to Chinese yards – often after discussion with ship owners who benefit from the low OPEX compared to membrane solutions.

- Retrofit: OXYMAT is seeing an increase of retrofit units – mainly for chemical tankers. Our products are popular because they are easy to integrate, and owners are interested in low operation costs.

OXYMAT marine nitrogen generators

We make it easy to serve every demand for nitrogen onboard. Our exclusive design integrates the product accumulation vessel in the product manifold, which allows you to switch from purging @ 95% to Blanketing @ 99.9% in only 15 min. Furthermore, we supply DRY AIR FOR VENTILATING CARGO AND DRYING HOLD SPACES. OXYMAT delivers high-end products. We offer a wide range of custom-made solutions, along with standard industrial solutions.

Applications include

- Drying of cargo tanks

- Inerting/purging cargo tanks

- Padding cargo tanks

- Pipe purging

- Super stripping

- N2 storage (HP)

- Inerting hull spaces (cofferdams)

- Gas freeing (dry dock)

.jpg)

Advantages of OXYMAT marine nitrogen generators

- Flexible operations (purity)

- Proven technology

- Smallest footprint

- Very lox OPEX compared to membrane solutions

- Highest quality N2 generators in the marine market

- Experience with all classification societies

- Plug-and-play solution

4.4 Electronics and laser cutting

For wave and reflow soldering in electronics. For laser cutting PSA is used to increase your productivity, reduce taper and optimise your process. Want to know more on how we can help? Ask one of our experts.

- Laser cutting: Increase your productivity, reduce taper and optimise your process. By using our nitrogen generator as your cutting gas, the laser beam melts the material, and the nitrogen blows away the molten material from the cutting groove.

- Electronics: Wave soldering: Primarily used for soldering through-hole components on to PCBs (nitrogen purity required 50-100 ppm). Reflow soldering: Used in large-scale electronics applications for soldering SMD components on to PCBs (nitrogen purity required 100-200 ppm).

- OXYMAT advantages: OXYMAT recognizes the requirement for a reliable source of high purity N2 for laser cutting and soldering. Our products are extremely durable and standard ROI is less than 2 years compared to gas delivered by gas companies.

Applications include

- Lower dross production

- Reducing oxidation

- Improving wettability

- Increasing quality of joints

- Less cleaning/maintenance

- Flux consumption/acidity

- Reduced defects/improved design

- Cheaper solder

- Less rework

Advantages of OXYMAT nitrogen generators

- Very low OPEX compared to cylinders or liquid gas

- Remove the hassle of handling cylinders

- No need to rely on external gas suppliers and fluctuating prices

- Increased productivity through higher cutting speed

- Clean cut edges

- No overheating from exothermic reactions

- Improved corrosion resistances

- Oxide-free cuts

- Dross-free finish

4.5 Mining and mineral processing

Nitrogen is primarily used to prevent mine fires and to inert abandoned areas of mines reducing oxygen level thus lowering risk of explosion. Want to know more on how we can help? Ask one of our experts.

- Mine fire prevention: In coal mines, nitrogen is primarily used to prevent mine fires and to inert abandoned areas of mines reducing oxygen level thus lowering limit of explosion.

- Non-aggressive firefighting source: Unlike other firefighting sources – water, powder, foam – nitrogen neither causes corrosion nor any other harm as other agents tend to. The consequences of using nitrogen are easily eliminated by just airing the premises.

- Stationary or mobile solution: Our PSA nitrogen gas generator will provide nitrogen at required flow and purity, and can be placed stationary or as mobile unit to extinguish pit fire at reasonable cost.

Advantages of OXYMAT nitrogen generators

- Inexpensive medium for inerting – only compressed air is required to produce nitrogen in required purity and quantity.

- Underground fire extinguishing – by reducing oxygen to below a level where burning is possible.

- Constant fire and explosion safe atmosphere – nitrogen injecting in abandoned areas or mines eliminates the threat of fire or explosion.

- Oxygen, heat, and fuel are frequently referred to as the “fire triangle”. Remove any one of these three elements and you will not have a fire or the fire will be extinguished. Essentially, fire extinguishers put out fire by taking away one or more elements of the fire triangle. What is easier than displacing oxygen with nitrogen and thereby eliminating the risks of fire.

4.6 Oil and gas

Nitrogen is commonly used in the oil and gas industry. Applications include well stimulation, injection, mothballing and pressure testing. Want to know more on how we can help? Ask one of our experts.

- Enhanced oil recovery: In some of EOR projects, nitrogen can be used to flood marginal fields.

- Pigging and purging: Nitrogen can be used as the driver to push the pigs through the pipe. Nitrogen can also be used to purge the pipeline after pigging has been completed.

- Well stimulation: Nitrogen lifting is used to initiate production on a well following workover or overbalanced completion. A coiled tubing string is used to apply the treatment, which involves running to depth while pumping high-pressure nitrogen gas.

Advantages of OXYMAT nitrogen generators

- Can be placed on a truck

- Able to reach high purities

- Designed for very high ambient temperatures

- Same unit can produce 95% and 99.9999%

- Very high quality workmanship – made for harsh conditions

4.7 Nitrogen for cable production

Our nitrogen generators optimize cable production by providing precise inerting, blanketing, and controlled atmosphere storage. The use of our nitrogen generators ensures superior quality and integrity of cables from manufacture to delivery. Want to know more on how we can help? Ask one of our experts.

- Controlled Atmosphere for Enhanced Cable Quality: Our nitrogen generators provide a precision-controlled atmosphere during the cable coating process, essential for superior insulation quality. By maintaining optimal nitrogen purity, our systems prevent air, moisture, and oxygen intrusion, enhancing the cable's electrical integrity and longevity.

- Efficient and Uniform Wire Galvanization: Our nitrogen generators enhance the wire galvanizing process by ensuring a uniform zinc coating. Designed to optimize nitrogen usage, they reduce operational costs and environmental impact by minimizing zinc wastage. This results in galvanized wires with consistent coating thickness and improved corrosion resistance, enhancing durability and performance.

- Nitrogen Atmosphere for Copper Wire Tempering: Our nitrogen generators are essential in the copper wire tempering process, providing a controlled atmosphere that prevents oxidation and enhances wire properties like resistance and flexibility. This ensures high reliability and efficiency in applications such as climatization and industrial heating-cooling systems

Applications include

- Nitrogen inerting and blanketing

- Controlled atmosphere storage (CAS)

- Nitrogen injection

- Sparging/stripping

- Purging

- Nitrogen flushing

Advantages of OXYMAT nitrogen generators

- Very low OPEX compared to liquid gas and cylinders

- Remove the hassle of handling cylinders

- No need to rely on external gas suppliers and fluctuating prices

- To maintain and preserve pharmaceuticals

- Serving as an inert replacement for air where oxidation is undesirable

- Slow down the decay process

- Extend the shelf life of pharmaceuticals

4.8 NItrogen for chemical manufacturing

Our cutting-edge PSA nitrogen generators empower chemical manufacturers with on-site nitrogen production capabilities. With a reliable source of high-purity nitrogen readily available, you can optimize your manufacturing processes, ensuring consistent product quality, efficiency, and safety at every step. Want to know more on how we can help? Ask one of our experts.

- Blanketing and Inerting: OXYMAT PSA nitrogen generators offer a dependable solution for creating inert atmospheres crucial for chemical processes. By blanketing reaction vessels and storage tanks with nitrogen produced on-site, the risk of oxidation and contamination is minimized, ensuring the integrity and quality of chemical products.

- Purging for Purity: During production, nitrogen serves as a purging agent, effectively removing impurities and contaminants from reactors and pipelines. Leveraging our advanced PSA technology, manufacturers can rely on a steady supply of high-purity nitrogen, guaranteeing the purity and consistency of chemical products.

- Pressurization for Precision: Nitrogen's ability to maintain precise pressure levels is instrumental in optimizing chemical reactions. By pressurizing reactors and vessels with nitrogen, manufacturers create ideal conditions for reactions, resulting in enhanced efficiency and product quality.

Advantages of OXYMAT nitrogen generators

- Able to reach high purities

- Same unit can produce 95% and 99.9999%

- Can be placed on a truck

- Designed for very high ambient temperatures

- Very high quality workmanship – made for harsh conditions

- Possibility for modular installation

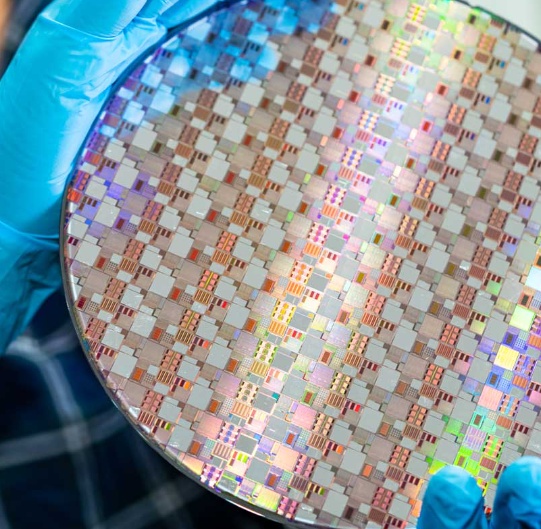

4.9 Nitrogen for Semiconductor Manufacturing

In semiconductor manufacturing, maintaining a contaminant-free environment is crucial. Our PSA nitrogen generators provide a reliable source of high-purity nitrogen, essential for various stages of production. Want to know more on how we can help? Ask one of our experts.

- Deposition: Enhance your deposition process with our nitrogen generators, ensuring pristine cleanroom standards. Our technology minimizes oxidation, maintaining the highest quality layers of thin films, and improving overall production efficiency.

- Purging: Achieve flawless patterning with our ultra-pure nitrogen. By preventing contamination, our generators support precise, high-quality patterning, resulting in superior semiconductor devices that meet the highest standards.

- Packaging: Protect your sensitive semiconductor components during packaging with our high-purity nitrogen. Our generators maintain an inert atmosphere, ensuring long-lasting functionality and reliability of your products.

Advantages of OXYMAT Nitrogen Generators

- Cost Savings: Reduce costs compared to bulk nitrogen supply.

- Consistency: Reliable on-site nitrogen production.

- Purity: High-purity nitrogen for critical manufacturing processes.

- Environmental Impact: Lower carbon footprint with reduced transportation needs.

Why Choose OXYMAT?

- Advanced Technology: State-of-the-art PSA technology for superior nitrogen purity.

- Reliability: Continuous nitrogen supply ensures uninterrupted production.

- Quality Assurance: Adherence to strict industry standards for semiconductor manufacturing.

- Enhance your semiconductor manufacturing process with the advanced capabilities of OXYMAT’s PSA Nitrogen Generators. Discover more about our solutions below.

5. Nitrogen special installation

5.1 Highly specialised nitrogen systems

We can engineer highly specialised nitrogen systems to meet your needs:

- Containerised: We are experts in containerised solutions.

- ATEX: Our units are placed on rigs and refineries around the world.

- Documentation: We can deliver documentation to the highest level. Our references include nitrogen systems for nuclear power plants.

- Climate: OXYMAT units are in operation around the globe, from Saudi Arabia to Greenland and Thailand.

- Altitude: We can engineer nitrogen systems for thin air. We have units operating in the Himalayas.

5.2 Plug-and-play nitrogen installations worldwide

We provides versatile nitrogen generation solutions across a variety of industries worldwide. Our technology, available in both in-frame and containerized formats, ensuring efficiency and reliability for every application. Our container and in-frame solutions are engineered to be ‘plug-and-play and user friendly.

- Marine and ship building: Our nitrogen generators enhance safety by creating inert atmospheres on ships, reducing the risk of fire and explosions in critical areas like engine rooms and cargo spaces..

- Oil and gas: In the oil and gas sector, nitrogen is essential for pipeline purging, maintaining reservoir pressure, and ensuring an inert environment to prevent fires and explosions during operations.

- Food and beverage: Nitrogen extends the shelf life of food and beverages by displacing oxygen in packaging (MAP), preventing spoilage and maintaining product freshness.

- Electronics and laser cutting: In electronics manufacturing, nitrogen prevents oxidation and contamination, crucial for producing high-quality components and devices. Our generators improve laser cutting processes by providing a high-purity nitrogen atmosphere, enhancing cut quality and preventing oxidation on metal surfaces.

6. Quality

With OXYMAT you will get gas generators of superior quality

A supplier you can rely on

OXYMAT acts as an efficient and reliable collaborator for customers as well as end-users.

Our production is highly standardised and all materials are produced according to offshore specifications. The only difference between a unit manufactured for an oil rig in the North Sea or a factory in Pakistan is the documentation package and the electrical equipment. Our standard product includes:

- stainless steel pipe sets and valves SS316L

- powder coating in C4 equivalent offshore specs – inside and outside pressure vessels

- pressure vessels designed for dynamic load

- Bürkert (GE) angle-seated process valves (SS316L)

Quality all around

All our sub-suppliers deliver premium quality products.

After more than 40 years in business, we have found that choosing the highest quality sub-suppliers is key to our own success.

We have worked closely with several of our suppliers for decades. A close cooperation with suppliers has resulted in units customised to OXYMAT’s requirements.

Our commitments to a healthier environment

- We continually improve and optimise our environmental management system

- We prevent pollution and reduce our impact on the environment

- We comply with all regulations and legislations including, but not limited to, ISO 14001 to protect the environment: Through regular training, we encourage our employees to perform environmental awareness in everything they do. We believe that our efforts to support the environment will create a solid foundation for success for future generations – and for our business.

Quality related certificates

We cooperate with Apragaz, Kiwa and DNV as independent inspecting authorities and specialists in certifying gas producers. Our quality management system is certified for compliance with:

- Company policies

- Certificates Denmark

- Certificates Slovakia

- EMS & Quality Objectives for 2023

7. Regulations

Working with gas: Safety, rules and regulations is part of who we are

We are the experts

- OXYMAT works within several industries with strict rules and regulations – we have become an expert on safety, rules and regulations, when it comes to use of gas in different industries.

- If your country specific regulation is not listed here, we are still sure, we are able to live up to them.

- Contact us to talk more about your specific restrictions and requirements.

-

+1,200 Medical references

+ 150 Marine references

+ 250 Food and beverages references

MEDICAL

Quality assurance is pivotal when working in the medical field. OXYMAT PSA generators hold all relevant approvals and are constantly working to comply to new standards.

MARINE

We have been a sub-supplier to the marine industry for decades. We know the characteristics and class societies of the industry and we can deliver according to the rules of: